Steel reinforced concrete is the strongest, most resilient structural material in the world. But did you know that there is another option to reinforce concrete? Glass fiber reinforced polymer (GFRP) is a rebar material that’s more corrosion-resistant, lighter, and stronger than traditional steel.

Logix ICF installers have enjoyed success with GFRP and in the post below, we will shine a light on what GFRP rebar is and what advantages it offers builders who reinforce their concrete with GFRP instead of steel.

What is GFRP Rebar?

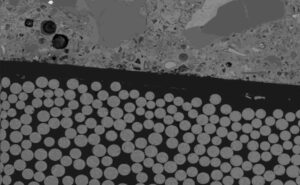

Fibers within Fiberglass Rebar (Photo Credit: ICFMA)

GFRP rebar is a type of synthetic reinforcement that’s made of a polymeric resin and strengthened with continuous glass fibers.

GFRP has been available as an alternative reinforcement material to conventional steel since the 1990s. This synthetic rebar has enjoyed a gradual rise in popularity thanks to the many key advantages it offers to concrete buildings over its steel counterpart.

What Advantages does GFRP Rebar Offer Over Steel?

Logix ICF installers have discovered there are three essential advantages of GFRP over steel as a reinforcement material: better corrosion resistance, lower weight, and greater strength. Below, we provide a more comprehensive analysis of GFRP benefits over steel.

GFRP Outranks Steel in Corrosion Resistance

GFRP has an ingrained resistance to corrosion that steel can never match.

That’s because GFRP contains zero iron, or any other element that could react with water, salt, or other substances that cause corrosion in steel rebar.

There’s simply no chemical process that could cause GFRP to corrode. This innate resistance to corrosion makes GFRP rebar an invaluable reinforcement material in regions where the risk of rebar corrosion is high, including coastal areas of the US and Canada.

GFRP Weighs Less Than Steel

Fiberglass rebar in transit (Photo Credit: ICFMA)

GFRP rebar weighs a mere 131 pounds per cubic foot, whereas steel rebar is over three times heavier, at 487 pounds per cubic foot. Weight is a significant factor in the amount of time and effort it takes to install reinforcement, with heavier rebar requiring more crew hours to place. Swapping steel rebar for its lighter GFRP equivalent is a simple way to boost construction times (and keep the crews happy).

GFRP Is Stronger Than Steel

Believe it or not, GFRP leaves steel lagging in every type of strength. GFRP has greater tensile, compressive, and fatigue strength than steel — and that’s despite the lower weight per volume.

GFRP vs. Steel Tensile Strength

Steel rebar has a tensile strength of 450MPa, and this strength diminishes in extreme temperatures. For example, steel becomes brittle when the temperatures dip significantly beneath the freezing mark. In contrast, GFRP has an astronomically higher tensile strength that ranges between 1,275-10,000MPa and remains stable despite changes in temperature.

GFRP vs. Steel Compressive Strength

GFRP has a compressive strength of 550MPa, which is only marginally higher than the 400MPa you get from steel reinforcement. Compressive strength is of little significance in rebar, though, as concrete stands up to compressive loads quite well and reinforcement is generally used to give concrete structures much-needed tensile strength.

Fatigue Strength

GFRP rebar’s fatigue strength (resistance to cyclic loads) is 20 times higher than that of steel rebar. Fatigue strength is of great importance in concrete reinforcement, as it allows rebar to withstand loads that get applied repeatedly — such as the cyclic lateral loads imposed by seismic activity or vehicular traffic on a concrete deck.

Rebar’s ability to withstand cyclic loads allows the reinforcement to remain intact during events that cause such loads, and provide the concrete with much-needed ductility.

Wrapping It Up

Reinforced concrete is the most durable, reliable, and disaster-resilient structural material and its reinforcement — a key component giving concrete tensile strength — has advanced over the past few decades, and materials such as GFRP now offer an effective rebar option.

Builders should consider GFRP as a worthy substitute for steel rebar because it’s more resistant to corrosion, has a lighter weight, and crucially, because it outperforms steel in tensile, compressive, and fatigue strength.

Content provided by: Andy Lennox, President at Logix Brands Inc